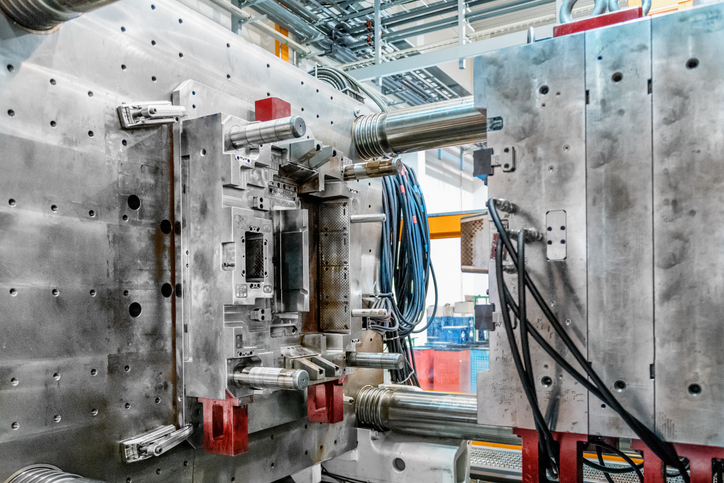

| Process | Injection |

| Materials | Re-Processed Plastic Recycled Polyethylene Polypropylene ABS Acrylic Nylon Polycarbonate Polyester Styrene |

| Clamping Force | 50 to 1,000 tons |

| Number of Cavities | 1 to 64 |

| Thickness | Up to .250 in |

| Area | Up to 480 in2 |

| Weight | Up to 5 lbs |

| Quality | Control |

| Documentation | First Article |

| Additional Services | Design Engineering Drop Shipping |

| Production Volume | Prototype to Production |

| Lead Time | 2 to 3 weeks (Production) 8 - 10 weeks (Tooling) |

Re-processed plastic, also known as recycled plastic, is material made from recovered plastic waste that is cleaned, sorted, shredded, melted, and reformed into new products. This process reduces the need for virgin plastic, cuts down on landfill waste, conserves natural resources, and lowers greenhouse gas emissions. Re-processed plastic is used to create various new products, including packaging, containers, automotive parts, and consumer goods.

Recycled plastic materials are types of plastic that have been recovered from waste and reprocessed into new products. Common types include:

- PET: Used in beverage bottles and containers, recycled into new bottles, packaging, and textiles.

- HDPE: Found in milk jugs and detergent bottles, recycled into new bottles, piping, and plastic lumber.

- PVC: Used in pipes and flooring, recycled into new pipes and building materials.

- LDPE: Found in grocery bags and shrink wraps, recycled into garbage can liners and floor tiles.

- PP: Used in yogurt containers and bottle caps, recycled into automotive parts and consumer products.

- PS: Found in disposable coffee cups and cutlery, recycled into insulation and light switch plates.

- Other Plastics: Includes materials like acrylic and nylon, recycled into textiles and automotive components.

Recycling these materials reduces the need for virgin plastic, minimizes landfill waste, and lowers environmental impact.

Polyethylene is a widely used plastic made from ethylene monomers. It comes in several types:

- High-Density Polyethylene (HDPE): Strong and dense, used for milk jugs, detergent bottles, and piping.

- Low-Density Polyethylene (LDPE): Flexible and less dense, used for plastic bags, shrink wraps, and food wraps.

- Linear Low-Density Polyethylene (LLDPE): Similar to LDPE with varied branching, used for stretch wrap and flexible packaging.

- Medium-Density Polyethylene (MDPE): Between HDPE and LDPE in density, used for gas pipes and fittings.

- Ultra-High-Molecular-Weight Polyethylene (UHMWPE): Extremely durable, used in medical devices, bulletproof vests, and conveyor belts.

Polyethylene is known for its versatility, chemical resistance, and durability, making it suitable for a wide range of applications.

Polypropylene (PP) is a versatile, durable thermoplastic polymer made from propylene monomers. It is known for its chemical resistance, lightweight nature, high melting point, and non-toxicity. Key uses include:

- Packaging: Containers, bottles, caps, and films.

- Automotive Parts: Bumpers, dashboards, and components.

- Textiles: Ropes, carpets, and reusable bags.

- Medical Devices: Syringes, pill bottles, and equipment.

- Consumer Goods: Storage bins, furniture, and toys.

- Industrial Applications: Piping systems and sheets.

Polypropylene is widely used due to its balance of performance, cost-effectiveness, and versatility.

ABS (Acrylonitrile Butadiene Styrene) plastic is a tough, rigid, and impact-resistant thermoplastic polymer. It is known for its chemical resistance, good thermal stability, ease of processing, and aesthetic qualities.

Uses:

- Consumer Electronics: Housings for computers and TVs.

- Automotive Industry: Car interiors, trims, and bumpers.

- Toys: Products like LEGO bricks.

- Household Appliances: Kitchen appliances and vacuum cleaners.

- Pipes and Fittings: Plumbing applications.

- 3D Printing: Popular material for printing.

ABS is favored for its durability, ease of manufacturing, and attractive finish.

Acrylic plastic, also known as PMMA, is a transparent, lightweight, and shatter-resistant thermoplastic. It offers excellent optical clarity and weather resistance, making it versatile for many uses.

Uses:

- Signs and Displays: For illuminated signs and retail displays.

- Windows and Skylights: As a glass alternative.

- Aquariums: In large tanks and aquariums.

- Automotive: For headlights and taillights.

- Furniture and Decor: In modern designs.

- Protective Barriers: For sneeze guards and safety shields.

Acrylic's durability, transparency, and ease of use make it ideal for various applications.

Nylon is a strong, durable, and heat-resistant synthetic thermoplastic polymer from the polyamide family. It is known for its high strength, elasticity, abrasion resistance, chemical resistance, heat resistance, lightweight nature, and low friction.

Uses:

- Textiles and Apparel: Clothing, hosiery, and activewear.

- Automotive: Engine covers, fuel lines, and air intake manifolds.

- Industrial Applications: Gears, bearings, and bushings.

- Consumer Goods: Toothbrushes, fishing lines, and kitchen utensils.

- Electrical and Electronics: Connectors and insulators.

- Construction: Fasteners and reinforcement materials.

Nylon's versatility makes it suitable for various industrial and consumer applications.

Polycarbonate is a durable, impact-resistant thermoplastic known for its optical clarity, heat resistance, and versatility. It is lightweight, maintains dimensional stability, resists UV degradation, and is easy to fabricate.

Uses:

- Protective Equipment: Safety glasses, helmets, and face shields.

- Automotive and Aerospace: Windshields, windows, and lighting components.

- Building and Construction: Skylights, roofing panels, and glazing.

- Electronics: Device housings, CDs, DVDs, and optical discs.

- Medical Devices: Equipment housings and sterilizable components.

- Consumer Goods: Eyewear lenses, water bottles, and reusable containers.

Polycarbonate's toughness and transparency make it ideal for various demanding applications.

Polyester is a durable, quick-drying, and wrinkle-resistant polymer widely used in textiles and various industrial applications. It is strong, lightweight, chemically resistant, and can wick moisture.

Uses:

- Textiles: Clothing, home furnishings, and industrial fabrics.

- Bottles and Packaging: PET for beverage bottles and food packaging.

- Films: Photographic films, magnetic tapes, and packaging films.

- Automotive: Tire reinforcements, seat belts, and upholstery.

- Construction: Ropes, safety belts, and tarpaulins.

- Industrial Applications: Conveyor belts, hoses, and filters.

Polyester's versatility and resistance to environmental factors make it a popular material in many industries.

Styrene is a colorless, oily liquid with a sweet smell, used primarily to produce plastics and resins. It is volatile, chemically reactive, and highly flammable.

Uses:

- Polystyrene Production: Used in products like disposable cups and insulation materials.

- ABS Plastic: Found in automotive parts, toys, and electronic housings.

- SBR (Styrene-Butadiene Rubber): Used in tires and footwear.

- Resins: Utilized in fiberglass, coatings, and adhesives.

- Copolymers: Forms materials like SAN and SMA for engineering plastics.

Styrene is essential in manufacturing various plastics and resins but requires careful management due to its potential health risks.

Our capabilities include processing materials with a thickness of up to 0.250 inches, an area of up to 480 square inches, and a weight of up to 5 pounds. These specifications enable us to handle a wide range of projects with precision and efficiency.

Plastic Injection Molding Services

Our plastic injection molding services are designed to meet all your needs with versatility and efficiency. We work with all thermoplastic materials, using both virgin and recycled materials, and can produce parts weighing up to 5 pounds. In addition to molding, we offer comprehensive assembly and secondary services to ensure your products are ready for market. Our reshoring capabilities and streamlined mold transfer process make it easy to move your production to our facilities, ensuring high-quality results and timely delivery.

Design in Manufacturability (DFM) Services

DFM refers to the process of designing products in a way that makes them easier, more efficient, and cost-effective to manufacture. When we examine a mold design, we evaluate and optimize the part design to ensure it can be successfully produced using the injection molding process, without complications or unnecessary expenses.

Key elements of DFM in mold design include:

-

Material Selection: Choosing the appropriate material that suits both the product's function and the manufacturing process.

-

Draft Angles: Ensuring that parts have proper draft angles to allow for easy ejection from the mold without damaging the part.

-

Wall Thickness: Designing consistent wall thickness to prevent defects like warping, shrinkage, or sink marks during the cooling process.

-

Undercuts and Complex Geometries: Minimizing or eliminating features that would require more complex or costly mold mechanisms like slides or lifters.

-

Parting Line and Ejector Pin Placement: Strategically positioning the parting line and ejector pins to maintain the aesthetic and functional quality of the part.

-

Gate Location: Ensuring gates (where molten plastic enters the mold) are positioned to promote even filling and avoid defects.

We are committed to integrating DFM principles in mold design, thereby reducing production time, costs, and potential defects--leading to a more efficient and reliable injection molding process for our Texas plastic injection molding customers and across the nation.