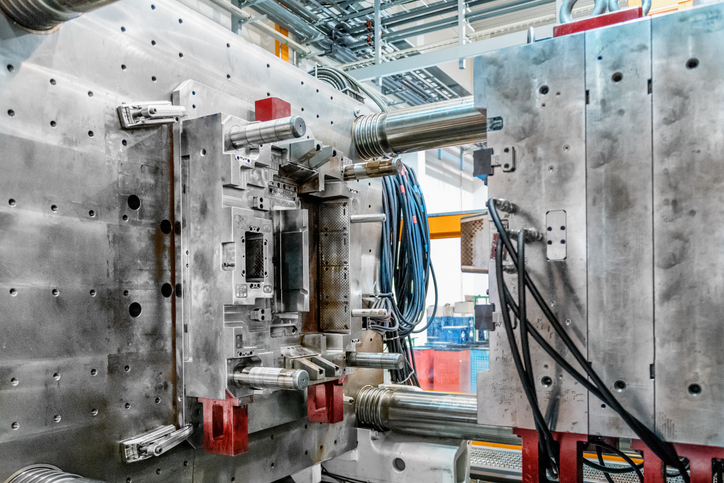

Injection molding machines, tooling, and facility setup can require significant upfront capital. Outsourcing eliminates the need for businesses to invest in expensive equipment, infrastructure, and maintenance.

By outsourcing, businesses can avoid the costs associated with hiring, training, and maintaining a skilled workforce to operate molding machines. This is especially valuable when considering specialized labor for complex processes.

Outsourcing allows businesses to scale production up or down based on demand without incurring additional costs for expanding facilities or adding equipment. This flexibility prevents excess inventory and idle machinery during slower periods.

Injection molding equipment requires regular maintenance and repair, which can add to operational costs. Outsourcing to a provider that maintains its own machines reduces the burden of maintenance costs on the business.

Outsourcing to specialized providers grants businesses access to the latest molding technologies, such as robotic automation and advanced quality control systems, without the need to purchase or upgrade equipment themselves.

A dedicated molding partner can streamline the production process, resulting in faster delivery times, which helps reduce time-to-market and increases revenue opportunities.

Metro Custom Plastics is strategically located to optimize shipping routes, reducing freight costs and ensuring timely delivery.

Outsourcing partners with established production systems are more likely to have efficient processes that minimize material waste and reduce associated costs.

Overflow molding is a technique primarily used in thermoset molding processes like compression or transfer molding. It involves the use of overflow cavities or wells that collect excess material once the main mold cavity is filled. This ensures complete cavity filling, improving dimensional accuracy and part integrity. The overflow material is later trimmed off after the part has cured.

This method is especially useful for producing high-precision components with excellent surface finishes and minimal defects. Common applications include electrical housings, automotive parts, and other components requiring tight tolerances and high strength.