Pest Control

Metro Custom Plastics supplies the pest control industry with essential plastic injection molded products, including durable bait stations, traps, sprayers, protective barriers, chemical dispensers, monitoring devices, and storage containers. Our products are lightweight, chemical-resistant, and cost-effective, ensuring safe and efficient pest management in various environments. By partnering with Metro Custom Plastics, pest control professionals can rely on high-quality, durable components to enhance their pest control practices.

Metro Custom Plastics: Innovating the Pest Control Industry with Plastic Injection Molding

Metro Custom Plastics is proud to offer specialized plastic injection molding solutions tailored for the pest control industry. With decades of experience and advanced technology, we provide durable, cost-effective, and customizable plastic components that enhance the effectiveness and reliability of pest control products. Whether creating traps, bait stations, sprayers, or protective housing, our expertise in plastic injection molding helps pest control companies deliver high-quality solutions that meet the needs of professionals and homeowners alike.

Benefits of Plastic Injection Molding in Pest Control

Plastic injection molding has revolutionized the pest control industry, providing manufacturers with a cost-effective, scalable method for producing durable and versatile components. Metro Custom Plastics leverages this manufacturing process to offer pest control companies the advantages of high-volume production with exceptional quality, consistency, and design flexibility.

1. Durable and Long-Lasting

The harsh environments faced in pest control require materials that are strong and resistant to wear and tear. At Metro Custom Plastics, our injection-molded parts are designed to withstand moisture, chemicals, and extreme temperatures, ensuring long-lasting performance. This durability is particularly critical in outdoor applications, where traps and bait stations are exposed to the elements.

2. Cost-Effective Manufacturing

Plastic injection molding allows for the efficient production of pest control products at scale. Once a mold is created, large quantities of parts can be produced quickly and with minimal waste, significantly lowering production costs. Metro Custom Plastics helps companies keep manufacturing costs down without compromising quality, making it easier to provide affordable pest control solutions for customers.

3. Precision and Consistency

Consistency is key in the pest control industry. Products such as bait stations, traps, and spray nozzles must be precise in their design to work effectively. Our injection molding process delivers tight tolerances and precise components with each production run, ensuring that every piece is identical and performs as expected. This level of precision helps pest control companies maintain a high standard of product performance and reliability.

4. Customizable Designs

At Metro Custom Plastics, we understand that every pest control product has unique design requirements. Plastic injection molding provides the flexibility to create complex shapes and detailed features that meet the specific needs of our clients. Whether designing intricate traps with multiple entry points or ergonomic sprayers for ease of use, our team works closely with pest control companies to develop custom solutions that enhance product functionality and market appeal.

5. Lightweight and Easy to Handle

Pest control professionals and homeowners benefit from lightweight products that are easy to transport and install. Plastic injection-molded components are significantly lighter than metal or other traditional materials, making them ideal for portable applications like traps, bait stations, and handheld sprayers. This ease of handling improves the user experience, allowing for quick deployment and maintenance of pest control products.

6. Resistant to Chemicals and Environmental Factors

Pest control products often come into contact with chemicals and other substances designed to eradicate pests. Metro Custom Plastics manufactures injection-molded components using materials that are resistant to these chemicals, ensuring that the products remain intact and functional over extended periods. Additionally, our plastic parts are resistant to UV exposure, moisture, and temperature fluctuations, making them ideal for both indoor and outdoor pest control solutions.

Applications in the Pest Control Industry

Metro Custom Plastics partners with pest control companies to develop plastic injection-molded components for a wide range of applications, including:

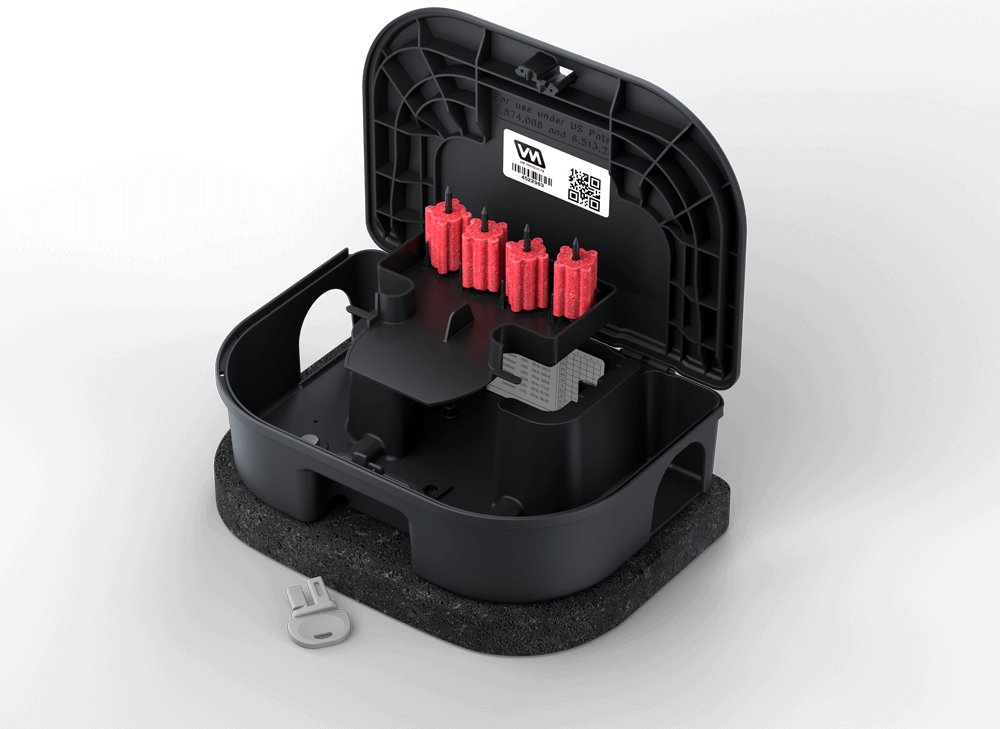

- Traps and Bait Stations: Durable, weather-resistant designs for outdoor use.

- Sprayers and Applicators: Lightweight, chemical-resistant parts for effective pest control treatments.

- Protective Housing: Enclosures for electronic pest deterrent systems that provide protection from the elements.

- Monitoring Devices: Custom components for insect monitors and pest detection systems.

Why Metro Custom Plastics?

With a commitment to quality, innovation, and customer satisfaction, Metro Custom Plastics is a trusted partner in the pest control industry. Our advanced plastic injection molding capabilities, combined with our ability to create durable, precise, and cost-effective components, make us the ideal choice for companies seeking to improve their pest control product offerings. From concept to production, we work closely with our clients to ensure that every component meets their exact specifications and exceeds their expectations.

Contact Metro Custom Plastics today to learn more about how our plastic injection molding services can support your pest control business.

Metro Custom Plastics has been incorporated in the State of Texas since 1972. During the past 50 years we have honed our skills in the injection plastics industry. We are diligent in the pursuit of continual improvement of quality products that meets, or exceeds, our customer's expectations.

Quick Navigation

Services

Copyright © 2024 Metro Custom Plastics. All Rights Reserved . Industrial Website by WYSIWYG Marketing